The stock timing on my car is now a matter of speculation. Since I am running the 2144 block with a turbo camshaft and a KE fuel system - none of which were made to go with each other - who knows how close I could get to California before the sirens go off! Since a cheap trick I have learned elsewhere to get a little more power from the normally aspirated 5 cylinder engine is to advance the timing (as detailed in my previous timing file for CIS) I am fiddling around with it on my current set up. The details in this file refer to KE Jetronic (1984-1987 on the US Coupe and 4k - the 1987.5 Coupe GT has KE3). I am also addressing the basic settings involved in adjusting the fuel mixture here. The key is to advance the timing to the peak power point. About 16-20 degrees btdc seemed to be right for me, and if you're not sure, about 12 is probably a good bet. You should have the following toys get the (static) fuel mixture adjusted for maximum driveability: Just for adjustment:

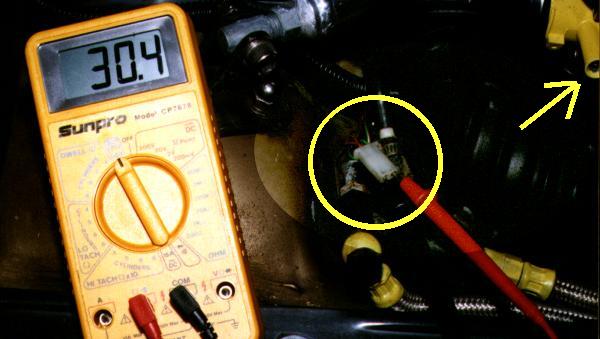

This work should be performed with the electrical systems off (do it between cooling fan cycles) and the cam cover vent hose clamped off. I am too lazy to clamp that hose, but I will probably start doing it once I replace my valve stem seals. Adjusting the basic settings on KE Jetronic requires a CO meter, really, but you can get things set without one. Two points I would like to raise here - if the car has not been "tampered" with, these settings are probably still correct and should be left alone - if the car is not running right, look elsewhere for your problems first. On the other hand, if they are set wrong, this will affect your cold starting ability since that depends on your "static" settings, and if they are way off the Control Pressure Actuator won't be able to lean or richen the mixture enough to get it to run right at all. Here is how to set them correctly. You can do this as a check on engine operation or in conjunction with screwing up the timing to get everything to run right with your new settings. First you hook up your meters. The current meter, set at a range that will register 0-50 mA or so, is inserted in the wires going to the control pressure actuator, using a little harness you can make or buy. When the car is at warm idle with no electrical gear running (and those pesky vent hoses clamped off!) the actuator current should "hunt" around a nominal value of 10 mA. If it does not hunt, or wander up a and down a bit around a central value, that is if it measures a consistent value, your car is not running in closed loop - something is stopping the ECU from taking over and managing the fuel system based on the oxygen sensor output. The most likely candidates for this failure are the oxygen sensor itself, the temperature switch (in the bottom of the top radiator hose flange), general wiring chaos, or a bad ECU. If this current is not in the correct range, it is adjusted by messing around in the little hole between the fuel distributor and the black rubber intake boot with the 3mm hex tool. There is a little set screw in there that adjusts the height of the air flow sensor plate arm, changing the relative mixture via the CPA. Clockwise for richer and lower CPA current, CCW for leaner and lower current. I like to work in increments of about 1/8 to 1/4 of a turn and work back and forth til I get it where it seems about right. You should remove the tool and rev the engine slightly before looking at the meter, to let the air plate settle in place. Do not rev the engine with the tool in place. The ISV duty cycle represents the amount of air allowed to bypass the closed throttle to keep the engine idle smooth and at the correct rpms (about 800 +/- 50). This is done with the meter connected to the two position connector that goes to nothing, usually hanging loose around the starboard strut tower somewhere. The duty cycle is to be set at 27% at idle, which is almost the lowest it will go at all - there seems to be a fixed minimum of 25%. When doing this sort of tuning work it is a good idea to check your spark plugs, cap and rotor, and be sure your air cleaner is in decent shape - otherwise you will be tuning the fuel systems to run "wrong" to compensate for worn out parts. This is also true of your various and sundry vacuum hoses - an air leak will throw everything off at idle, you will adjust for it, but it will be off by different amounts at other rpms and loads. Below are photographs of some of what is described above... The circle is around the ISV duty cycle test point. The arrow points to the idle adjustment screw.   The arrow points at where the Control Pressure Actuator plug is pulled and jumped via the adapter harness. The second picture is a close up of this device off the car. The third picture is the adapter harness I built for this measurement.

Here is a schematic diagram of the entire system:  |