We start with a working NG-code (87.5 coupe GT; 88-91 80Q, 90, 90Q) engine:

$350 in new parts to try to make it run worse:

The real goal here is to replace the noisy lifters (250,000 mile service). Since getting in there will expose the fuel injectors nicely, I figured I would pick some up and test mine (for flow and spray pattern), replacing them if indicated. So let's get started: Remove vacuum lines from intake manifold.

Undo the bolts holding the top half of the intake manifold in place.

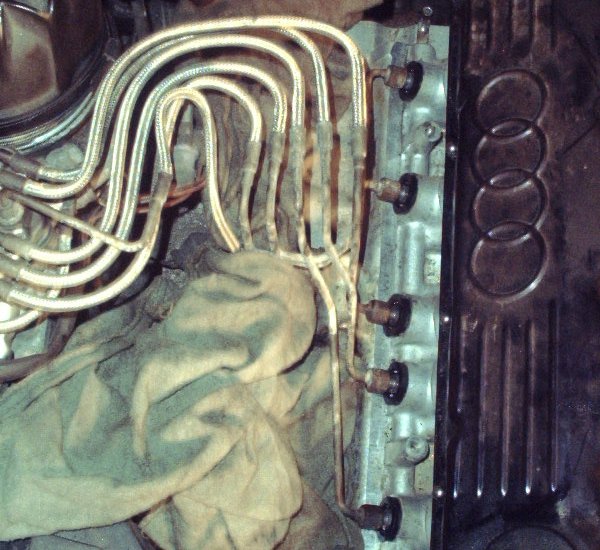

You should cover the holes in the bottom half of the manifold with a rag or two to prevent dirt, bolts, rocks, and hail from falling in while you work. Remove ISV and its hoses, inspect for damage. Remove the two bolts that hold the metal strips over the injectors and take off the strips. Pull the injectors out of the lower half of the intake manifold. This is actually quite easy, and although I used the proper tool for it, they would probably have come out by hand.

At this point, you have the injectors out, but still stuck in these crappy bakelite-ish plastic shroud thingies.

You can at least test their flow characteristics before going any further.

You are looking for two things - one, do they all spray the same amount in the same time (that's why it is nice to have identical containers!), and two, do they all have a nice, cone-shaped well-atomized spray.

Mine sprayed equally, but a bit streamy and uneven rather than the ideal. Since I am going to replace them, now it is time to remove the black plastic shrouds from the injectors so the injectors can be unbolted from the fuel lines. My black shrouds came off in pieces, they were so brittle. Luckily I had a set from an old parts car that were removable and reusable.

Undo the injectors from the lines, making sure to keep everything clean.

At this point you can either reverse the process to put everything back together, or keep going, if there is more work to be done in here. In my case, I am going in a bit further to replace my tired old ticking hydraulic valve lifters (cam followers). |